What do we do?

Go-no go gauges, setting gauges and checking gauges.

We are specialized in the manufacture of go-no go gauges and special setting gauges following customer's requirement. Different characteristics can be measured, such as diameters, lengths, thicknesses, Torx fingerprints, hexagons, conical parts. The most demanded checking gauges for the machinery sector are Iso / Asa, Morse and Hsk systems.

- Limit gauges: Plugs, rings and snap gauges.

- Reference standard: ISO 1938-1: 2015.

- Splined gauges: plugs and rings, with involute or rectilinear teeth.

- Reference standards: DIN 5480, ISO 4156, NFE 22-142, ANSI B92.1-1996.

- Threads: plugs, rings and snap gauges.

- Normas de referencia: Reference standards: DIN 103 (trapezoidal), DIN 405 (round), DIN 477 (butane bottles), NFE03-611 (asymmetric thread), ISO 1502 (metric), ANSI / ASME B1.2 (American), BS 919 (whitworth), ISO 228 (gas), ISO 7, ANSI / ASME B1.20.1 (NPT), ANSI / ASME B1.21.5 (NPTF).

- CEI / Ansi: : gauges defined in their respective standards for electrical insulators.

- Reference standards: EN 60423: 2007 and C29.2-1992 (R1999).

Verification tooling

Manufacturing of tools under EVEC's own design (we have our own technical office), following definition or needs of our customers, or following their design. The measurement can be done by attributes (go-no go and montability conditions), by variables (setting gauges+ comparator clock for obtaining values), or a combination of both modalities..

High precision grinding

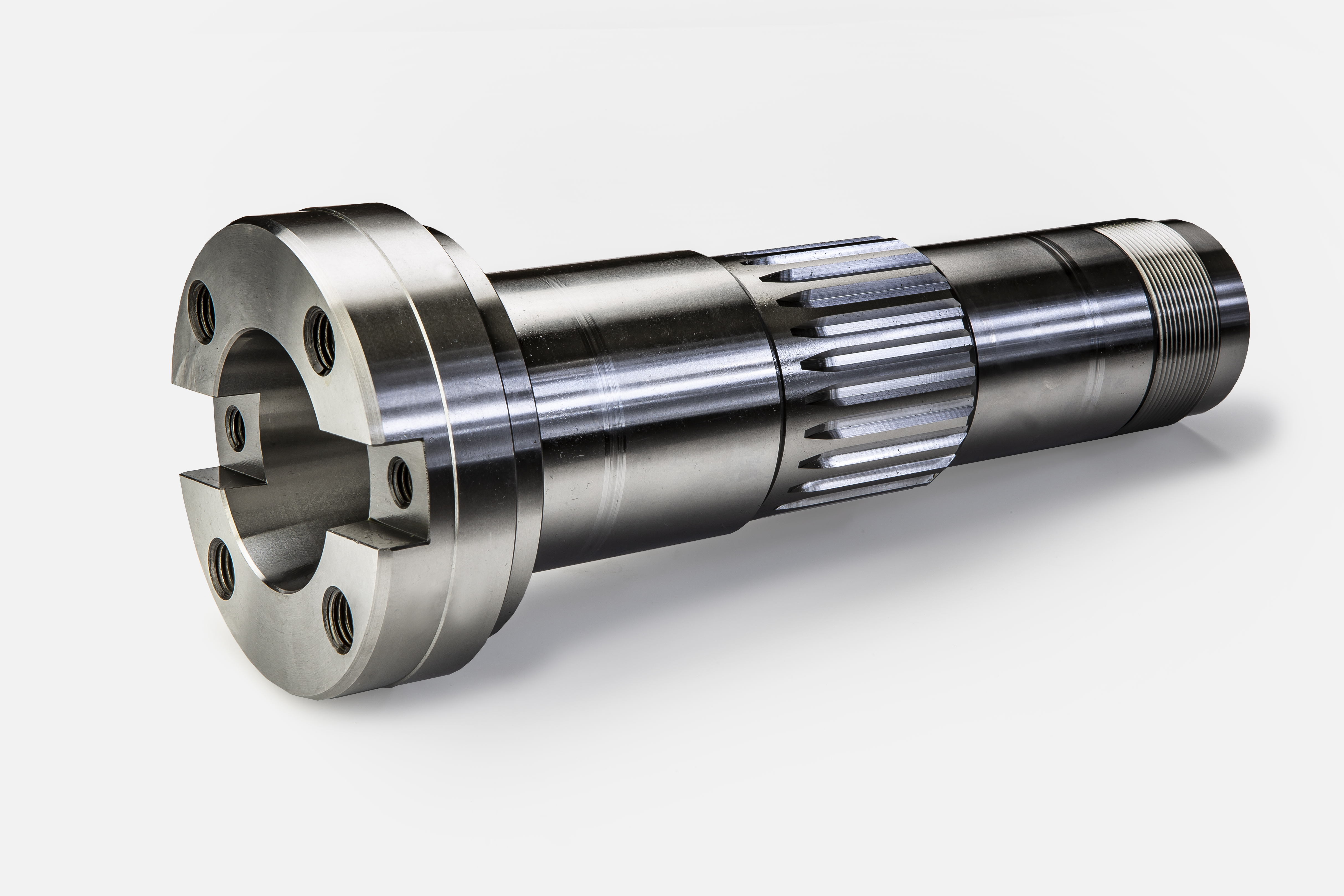

We are specialists in all type of grinding (splined parts, threads, external grinding, internal grinding, plain grinding, boring) in critical parts. Our customers order also the complete piece manufacturing (in this case we do all the subcontracting process, roughing operations, heat treatments and surface coatings), or specific grinding operations (they subcontract EVEC the specific process of grinding ). Most national machine tool firms trust in EVEC the construction or grinding of the most delicate parts of their machines, so as main shafts, couplings, sleeves or transmission shafts.

Calibration or measurement service

To complement our services, we offer the verification service to those customers who have the need to perform periodic calibrations, because gauges should follow a calibration plan (in order to know the variation that may have suffered over time and its use).